The Korea Institute of Electrical Engineers has surpassed the limit of ultra-high-definition display with 3D printers. (Photo: Korea Institute of Electrical Engineers)

The Korea Electrotechnology Research Institute said it has exceeded the limit of ultra-high-definition display with 3D printers. They printed 620nm pixels in a three-dimensional structure and attracted attention by realizing resolutions 50 times higher than 8K QLED TVs.

Especially, the technology can be applied to wearable devices, and future development is getting more attention.

Realizing Reality of Technology Independence

Recently, many companies around the world are fighting ultra-high resolution wars in the display field of various electronic products such as TVs and smartphones.

In particular, virtual reality, which is the key keyword of the fourth industrial revolution, is demanding a higher level of image quality. Korean researchers are spurring the development of technology that can produce 'nano display', which boasts overwhelming resolution using 3D printing technique.

Therefore, Dr. Pyo Jae-yeon and Seo Seung-kwon of the Korea Electrotechnology Research Center (KERI) Nano Fusion Research Center, a government-funded research institute under the National Science and Technology Research Council of the Ministry of Science and ICT, have developed Nanophotonic 3D printing technology that can manufacture ultra-high resolution displays using 3D printers. Based on this technology development, they have also achieved complete technological independence from 3D printing materials to source technologies and equipment.

3D printing full color quantum dot ink (photo; Korea Electrotechnology Research Institute)

3D Printing Technology, Application to Display Industry

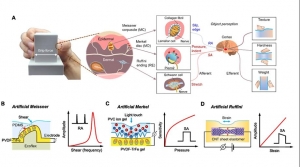

The results of the Korea Electrotechnology Research Institute are the technology that allows the Quantum Dot pixels of the display panel to be printed in a three-dimensional structure. Quantum dot is a nanoparticle that can generate various colors of light when received light or electric stimulus. It is actively used as a light emitting material for display of various electronic products such as TV, smartphone, tablet, etc. because of high color purity and stability.

Currently, the display manufacturing method is fabricating pixels by thinly applying quantum dot. Often, the high resolution means that the number of pixels on one screen is large. If the pixels are gathered at high density, the images and photographs can be expressed precisely and delicately.

Many companies have tried to increase the resolution by reducing the size of the pixels to increase the number of pixels, but there has been a problem that the brightness of the light generated by the reduced size is limited.

The Korea Electrotechnology Research Institute has developed a technology that can manufacture ultra-high resolution displays with nanometer pixels using 3D printers to improve these problems.

They decided that if the pixels were made in a three-dimensional structure rather than a thin film, they would be able to secure the brightness required for high resolution. Using their own 3D printing technology, they produced pixels with a width of 620 nm and a height of 10,000 nm. This solves the problem of brightness restriction of light through pixel production of 3D structure rather than existing 2D. As a result, the brightness more than twice as bright as the existing thin film can be realized in full color of red, green and blue.

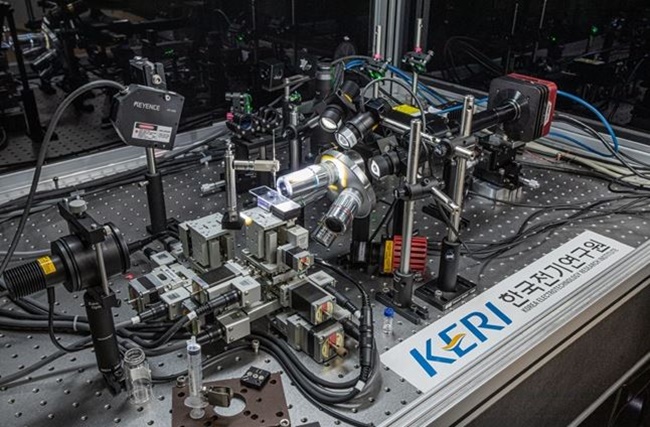

Nanophotonic 3D printing technology equipment (photograph; Korea Electrotechnology Research Institute)

Compared to PPI (Pixels Per Inch), which is an indicator of resolution, the technology of the Korea Electrotechnology Research Institute can overtake the existing TV, notebook, and smartphone levels by showing 5,600PPI-level three-color pixels, and can achieve resolutions more than five times higher than the current limit level of 1,000PPI. This is a level that can be widely used in future advanced display fields such as virtual reality related technology and beam projector that require ultra-high resolution.

Above all, the nanophotonic 3D printing technology of Korea Electrotechnology Research Institute can be directly printed on polyimide and PET (Polyethylene Terephthalate) films, which are flexible substrate materials, and can be applied to wearable and rollable devices.

“Unlike 3D printing research, which often depends on foreign equipment, our technology has achieved complete technological independence from 3D printing materials to source technology and equipment,” said Dr. Pyo Jae-yeon, who said, “It is hard to find cases where 3D printing technology is applied to the display industry in the world.”

![[BUTECH 2025] 케이지오토, 이더넷 스위치, 슬림형 SSR, 포토센서, 카운터 타이머 등 신제품 공개](https://file.yeogie.com/img.news/202505/md/z1r4y2A7fE.jpg)

![[인터뷰] LS엠트론(주), 기술교육아카데미의 혁신 파트너십으로 고객의 성장을 디자인하다!](https://file.yeogie.com/img.news/202506/md/EHkQ0TcnDp.jpg)

![[KOPLAS 2023 Review] 플라스틱의 지속 가능한 미래를 위한 키워드, ‘친환경’과 ‘탄소중립’①](https://file.yeogie.com/img.news/202303/md/jdyPATuPF3.jpg)

![[KOPLAS 2023 Preview] 삼보계량시스템(주), 플라스틱 펠렛 'PLATONⅡ'로 고객 눈길 사로잡다](https://file.yeogie.com/img.news/202302/md/4QINfMIE2G.jpg)